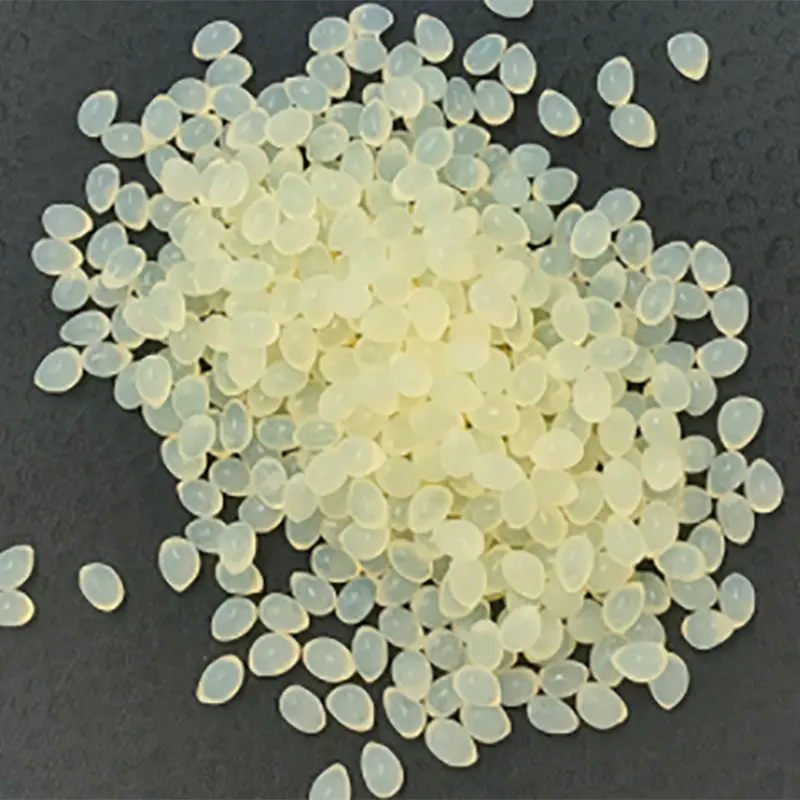

What is Granules hot melt adhesive?

Granules hot melt adhesive is a thermoplastic bonding material supplied in small pellet or granule form. It becomes liquid when heated and solidifies quickly after cooling, forming a strong bond without the need for solvents or water.

Why choose granular form instead of sticks or blocks?

Granules are easier to feed into automatic or semi-automatic hot melt machines. They melt evenly, reduce waste, and allow more accurate control of adhesive quantity during production.

What industries commonly use granular hot melt adhesive?

It is commonly used in carton sealing, labeling, bookbinding, woodworking, furniture manufacturing, hygiene products, and some automotive or electronics applications.

Is granular hot melt adhesive environmentally friendly?

Many hot melt adhesives are solvent-free and produce low emissions during use. Some formulations are designed to meet recycling or food packaging standards, depending on application requirements.

How should granular hot melt adhesive be stored?

Granules should be stored in a clean, dry environment, away from direct sunlight and excessive heat. Proper storage helps maintain stable melting behavior and bonding performance.

Can different granules be mixed together?

Mixing different types is generally not recommended, as formulations may have different melting points and flow characteristics. Using one consistent adhesive type ensures stable results.

What Are the Types of Granular Hot Melt Adhesive?

Granular hot melt adhesives can be classified based on their chemical composition and performance characteristics. Each type is designed for specific bonding needs, temperature ranges, and materials.

|

Type

|

Main Characteristics

|

Typical Applications

|

|

EVA (Ethylene Vinyl Acetate)

|

Good flexibility, cost-effective, easy processing

|

Carton sealing, packaging, bookbinding

|

|

Polyolefin (PO)

|

Low odor, good heat resistance, clean appearance

|

Food packaging, hygiene products

|

|

Polyamide (PA)

|

High strength, chemical and oil resistance

|

Automotive parts, electronics

|

|

PUR (Polyurethane Reactive)

|

Moisture-reactive, very strong and durable bond

|

Woodworking, furniture edge banding

|

|

Metallocene-based

|

Stable viscosity, good aging performance

|

High-speed packaging lines

|

EVA-based granular adhesives remain the widely used due to their balance of price and performance. Polyolefin and metallocene types are often selected for cleaner processing and improved temperature resistance. Polyamide and PUR adhesives are typically used in applications where long-term durability and higher bonding strength are required.

Differences in Use and Characteristics Between White or Opaque Hot Melt Adhesive

White or opaque hot melt adhesives are commonly discussed in packaging and assembly applications. While they may appear similar, there are practical differences in appearance, use, and performance considerations.

White hot melt adhesive usually provides a cleaner and more uniform look, which is preferred for visible packaging seams. Opaque adhesives may appear slightly cloudy or milky, which is acceptable for hidden bonding areas.

White adhesive lines are easier to inspect during production, making them useful for quality control. Opaque adhesives may blend more with certain materials, reducing visual contrast.

White hot melt adhesives are often formulated for general packaging and labeling. Opaque versions may include fillers or additives designed to improve gap filling or reduce cost.

Both types can bond paper, cardboard, plastics, and some fabrics, but specific formulations may perform better on certain surfaces. Selection should be based on adhesion needs rather than color alone.

There is usually little difference in melting behavior based solely on color. Performance depends more on the adhesive type (EVA, PO, etc.) than on whether it is white or opaque.

Opaque hot melt adhesives may be slightly more economical in some applications, especially where appearance is not critical.

English

English 中文简体

中文简体