Industry Knowledge Extension

What factors influence the price of hot melt adhesives?

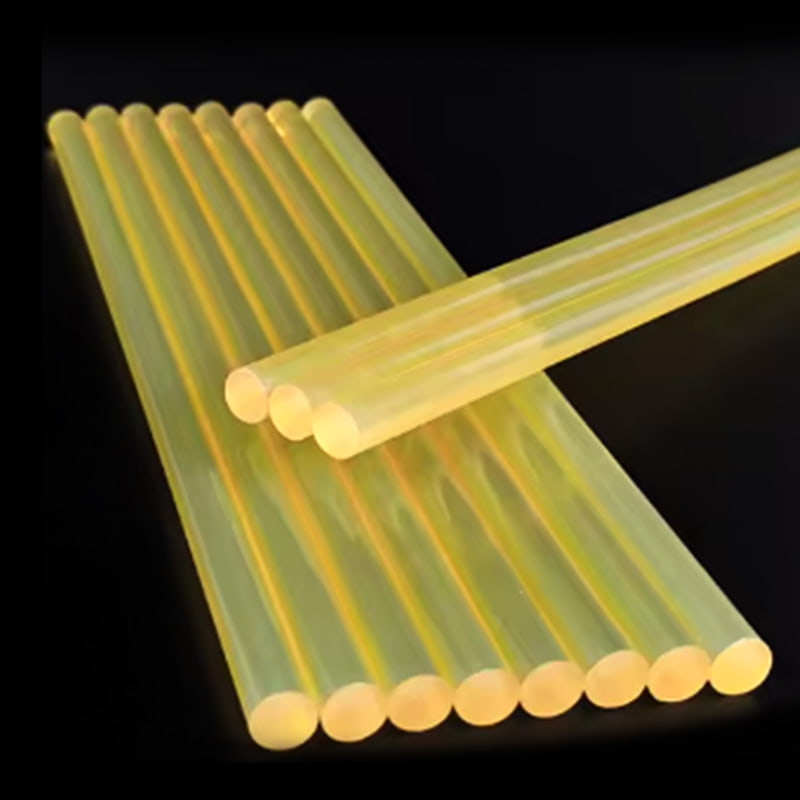

The remarkable versatility and widespread adoption of hot melt adhesives (HMAs) across industries from packaging to woodworking can be attributed to their unique combination of performance and practicality. Unlike solvent-based or water-based adhesives, hot melts are thermoplastic materials applied in a molten state that solidify upon cooling to form a bond. This fundamental characteristic underpins their appeal, offering rapid setting times, clean application, and strong initial tack. As with any industrial material, understanding the economic and technical factors behind HMAs is key to effective selection and use.

The pricing of lower-cost hot melt adhesives is influenced by a combination of material, production, and market factors. At the core is the raw material cost, predominantly determined by the price of base polymers like ethylene-vinyl acetate (EVA) and the paraffin or tackifying resins blended with them. As these are petroleum-derived commodities, their cost is sensitive to global oil prices and supply chain dynamics. The formulation complexity also plays a direct role. A simple, general-purpose adhesive for bonding porous materials like paper or cardboard requires fewer specialized additives than a formula designed for challenging plastics or high-temperature resistance, keeping production costs lower.

Manufacturing and supply chain scale contribute significantly. Large-volume production runs and streamlined logistics can reduce per-unit costs, allowing manufacturers to offer economical options, particularly for standard-grade products purchased in bulk. Finally, the competitive landscape within the industrial adhesives market encourages price adjustments to meet the demands of cost-sensitive applications and high-volume users, making certain HMA types accessible for everyday use.

A Balance of Performance and Processability: Advantages of EVA Hot Melt Adhesives

Among the various polymers used, EVA-based hot melts are notable for their balanced profile, which supports a wide range of common applications.

- Broad Substrate Compatibility and Reliable Adhesion

EVA hot melts exhibit a favorable balance of adhesion to many materials. They generally form reliable bonds with porous substrates such as paper, cardboard, wood, and fabrics. This versatility makes them a practical choice for industries like packaging, bookbinding, and basic assembly, where a single adhesive may contact multiple material types.

- Ease of Application and User-Friendly Handling

EVA formulations are recognized for their stable melt viscosity and good wetting characteristics. This translates to consistent performance in application equipment, ranging from industrial tanks to hand-held guns, with reduced risk of charring or nozzle clogging. Their relatively low application temperatures can also contribute to energy savings and safer working environments compared to some higher-melt-point alternatives.

- Economic Efficiency in Material Cost

As one of the established HMA chemistries, the production of EVA hot melts is streamlined and cost-effective. The raw materials are readily available, and the manufacturing processes are optimized. This economic efficiency makes EVA-based adhesives a practical option for high-volume, cost-conscious operations where their performance characteristics meet the application requirements without necessitating a more specialized and expensive polymer system.

Why are hot melt adhesives so popular?

Hot melt adhesives have become integral to modern packaging operations, valued for their contribution to speed, efficiency, and reliability. In this context, their primary function is to construct, close, and seal various types of packaging, such as corrugated cartons, cardboard boxes, and disposable containers. The key attribute driving this adoption is the rapid setting speed of hot melts. Unlike other adhesives that require drying or curing time, hot melts solidify in seconds upon cooling, enabling immediate handling of packaged goods and supporting high-speed production lines without bottlenecks. This speed is complemented by strong initial tack, which helps hold flaps and seams securely in place during the setting process. Furthermore, hot melts are applied as 100% solid materials, meaning they contain no water or solvents. This characteristic eliminates concerns about warping water-sensitive paper-based materials and removes volatile organic compound (VOC) emissions from the production environment. Modern packaging HMAs are also engineered to meet specific needs, such as forming bonds that remain intact across a range of temperatures during storage and transit, or offering specific open times to accommodate the machine's operational pace. From sealing everyday shipping boxes to assembling intricate point-of-purchase displays, hot melt adhesives provide a clean, fast, and adaptable bonding solution that aligns with the demands of efficient packaging logistics.

English

English 中文简体

中文简体