Industry Knowledge Extension

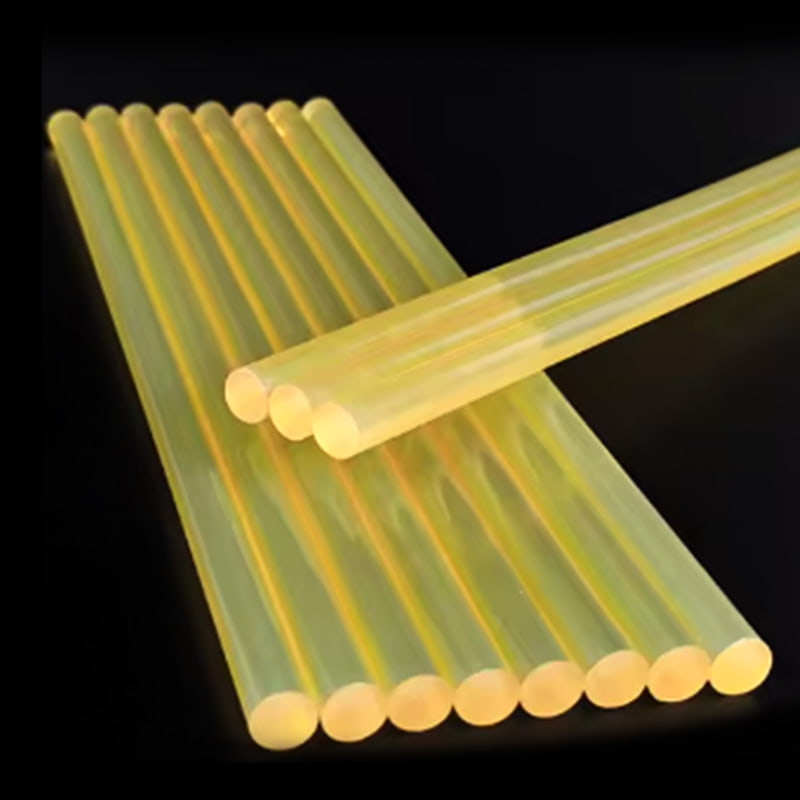

How Is High Viscosity Hot Melt Adhesive?

High viscosity hot melt adhesive refers to an adhesive that has a thicker, more resistant flow when heated and applied. Compared with low or medium viscosity adhesives, it flows more slowly and provides better gap-filling capability, which can be important in certain bonding situations.

High viscosity adhesives are commonly used when substrates have uneven surfaces or when a thicker adhesive layer is required to improve bond stability. They are also suitable for applications where adhesive stringing needs to be controlled or where the adhesive must stay in place without excessive spreading.

|

Aspect

|

Description

|

|

Flow behavior

|

Thick and slow-flowing when molten

|

|

Gap-filling ability

|

Strong, suitable for uneven surfaces

|

|

Initial tack

|

Usually high, supports fast positioning

|

|

Application control

|

Good bead definition, less dripping

|

|

Common forms

|

Granules, blocks, pillows

|

|

Typical uses

|

Carton sealing, woodworking, assembly

|

High viscosity hot melt adhesives are often chosen for vertical or angled applications, where lower viscosity products may run or drip. However, they may require higher application temperatures or stronger pumping systems to ensure stable flow.

High viscosity hot melt adhesive offers reliable bonding for applications that demand controlled application and enhanced gap coverage, provided that equipment and temperature settings are properly matched to the adhesive formulation.

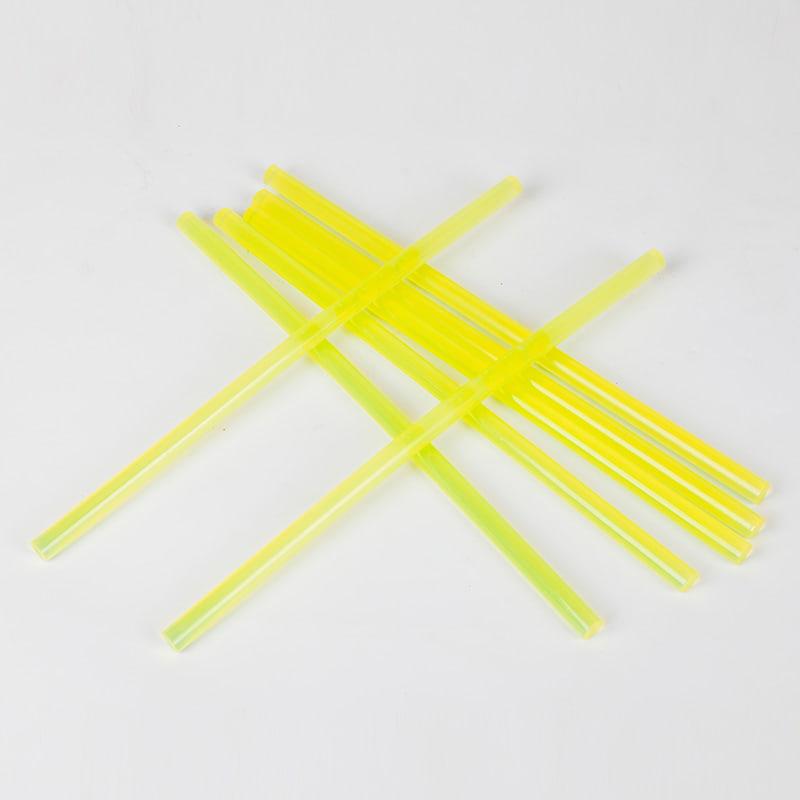

What Are the Properties of White Hot Melt Adhesive Granules?

White hot melt adhesive granules are commonly used in packaging, labeling, and general assembly. Their popularity is related not only to performance, but also to their appearance and processing convenience. The main properties can be summarized as follows:

- Uniform color and appearance

White granules provide a clean and consistent bonding line, which is helpful for visible packaging seams and quality inspection.

These granules are designed to melt evenly, reducing the risk of burning or inconsistent flow during application.

- Good adhesion to common substrates

White hot melt adhesive granules typically bond well to paper, cardboard, wood, and certain plastics.

Many white granule formulations balance flow and control, making them suitable for both manual and automated equipment.

- Low odor during application

Compared with some darker or filled adhesives, white granules often produce less noticeable odor when heated.

They tend to leave less residue on equipment, which helps reduce maintenance frequency.

Once applied, the adhesive cools and sets quickly, supporting efficient production speeds.

- Wide application compatibility

White hot melt adhesive granules are available in EVA, polyolefin, and other base materials, allowing selection based on performance needs.

What is a custom hot melt adhesive?

A custom hot melt adhesive is formulated to meet specific requirements such as viscosity, open time, bonding strength, color, or temperature resistance, based on the user’s application and equipment.

Why choose a custom formulation instead of a standard product?

Standard adhesives may not always perform with certain substrates or production speeds. Custom formulations help improve bonding consistency and reduce production issues.

Which parameters can be customized?

Common adjustable parameters include viscosity, softening point, setting time, color, adhesion to specific materials, and temperature resistance.

Is custom hot melt adhesive more expensive?

Custom products may have higher initial costs, especially for development and testing. However, they can reduce waste, downtime, and rework in long-term use.

What information is needed to develop a custom adhesive?

Manufacturers usually need details about substrates, application method, operating temperature, production speed, and environmental conditions.

Can custom adhesives be used in existing equipment?

In cases, custom hot melt adhesives are designed to work with existing machines, but equipment compatibility should always be confirmed.

How long does development take?

The timeline depends on complexity, but it typically includes formulation, sample testing, and performance validation before full production use.

Custom hot melt adhesives allow manufacturers to better align adhesive performance with real production conditions, supporting stable quality and efficient operation.

English

English 中文简体

中文简体