The Practical Advantages of Glue Block Hot Melt Adhesive

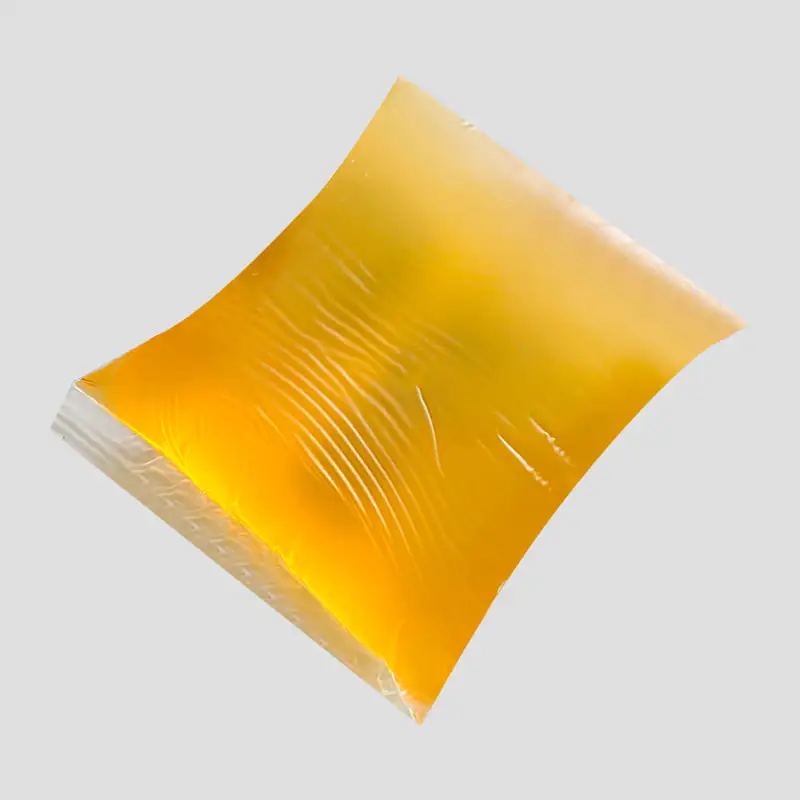

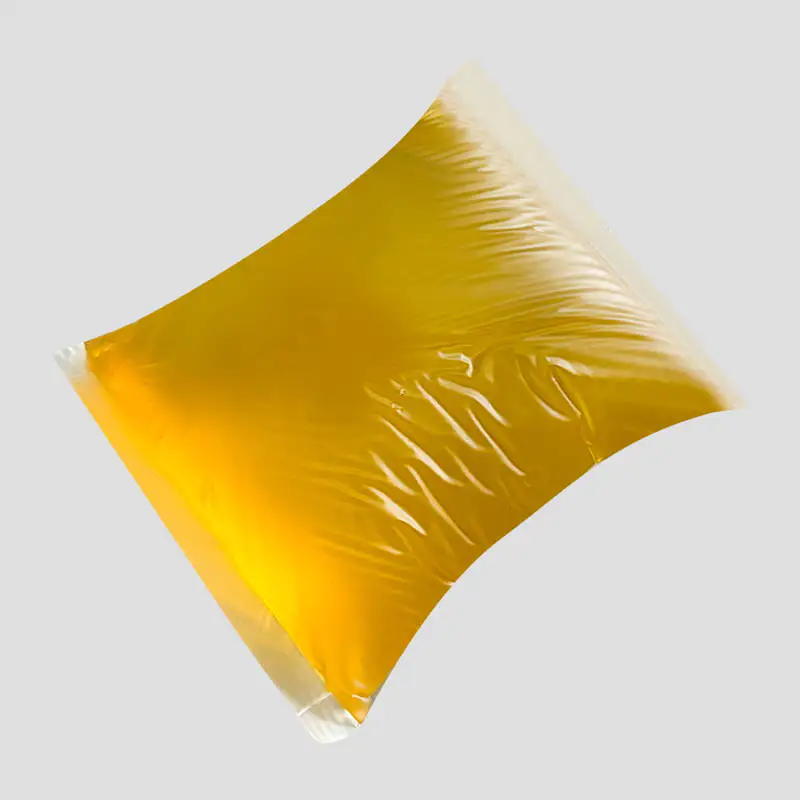

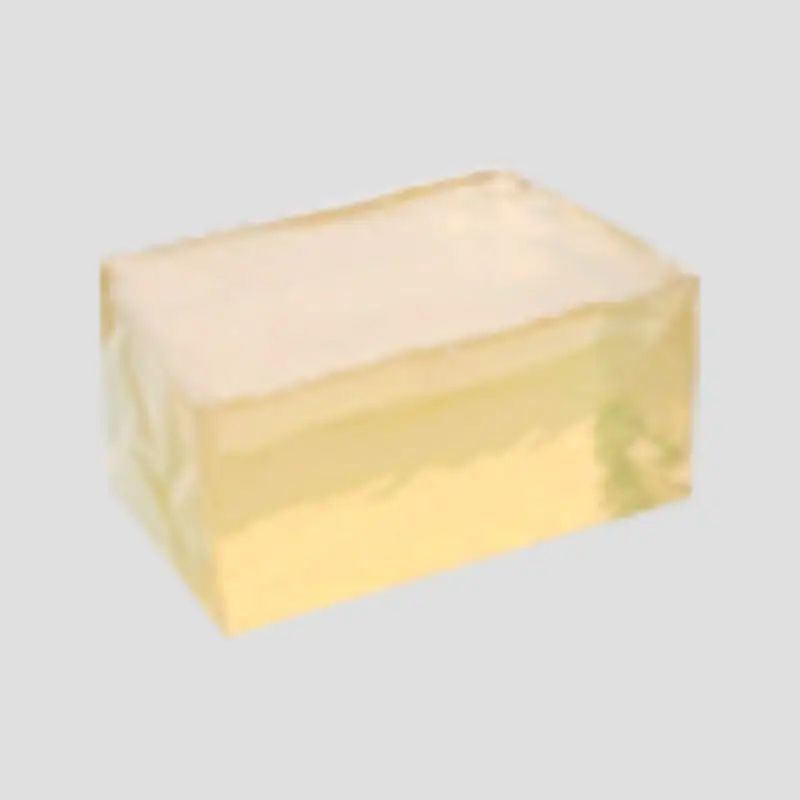

Glue block hot melt adhesives, often supplied in large, solid bricks or smaller, handheld blocks, are a staple in many settings, from packaging plants to workshops. Their format offers several key operational benefits.

- Ease of Handling and Storage: The solid block form is straightforward to handle, store, and inventory. Unlike granules or pellets, blocks are less prone to spilling and are typically packaged in simple, space-efficient cardboard boxes without the need for complex hopper systems.

- Reduced Waste and Cost-Effectiveness: Blocks allow for manual or semi-automated feeding into melt tanks with control over material usage. There is minimal overfeed or loss, making them a economically efficient choice, especially for operations with variable or lower-volume usage.

- Simplified Application for Manual Use: For manual guns designed to accept block sticks, the user-friendly format enables quick reloading without mess. Smaller block sticks are ideal for repair work, woodworking, prototyping, and craft projects where precision and convenience are important.

- Consistent Melt Characteristics: Manufactured to a specific size and shape, blocks can provide a consistent melt volume and rate in appropriately designed equipment, contributing to stable application performance.

- Material Versatility: Block adhesives are formulated in a wide array of materials, including standard EVA (ethylene-vinyl acetate), polyolefin, and polyamide, catering to needs from general-purpose bonding to more demanding applications involving heat resistance or adhesion to challenging substrates.

The Growing Popularity of PSA Hot Melt Adhesive

Pressure-sensitive hot melt adhesives represent a sophisticated evolution of traditional HMAs. Unlike standard hot melts that simply bond as they cool, PSA hot melts remain permanently tacky at room temperature, creating instant, repositionable bonds upon the application of light pressure. Their popularity spans industries from packaging and product assembly to disposable hygiene and graphics.

Instant Bonding Without Full Cure

A primary driver for PSA HMA popularity is the immediate adhesive tack they develop upon cooling. This eliminates the need for clamping or prolonged pressure during assembly, drastically speeding up production cycles. In automated settings, this allows for faster line speeds and immediate further processing of assembled items.

Versatility Across Diverse Materials

PSA hot melts are engineered to adhere to a vast range of substrates—including plastics, metals, treated surfaces, films, and foams—where traditional adhesives might struggle. This versatility makes them a single adhesive solution for complex assemblies involving multiple materials, simplifying inventory and application processes.

Clean and Efficient Application

Like all hot melts, PSA variants are 100% solid and solvent-free. They emit no volatile organic compounds (VOCs), creating a safer work environment and eliminating concerns over solvent retention or flammability. The application process is clean, with precise patterns possible through modern dispensing equipment, reduce waste.

Enabling Innovation in Design

The properties of PSA hot melts have enabled new product designs and manufacturing methods. They are crucial in creating removable labels, temporary fixtures, and bonds that require some flexibility or impact resistance. Their use in non-woven products and disposable items highlights their importance in modern, high-volume manufacturing.

What is the primary difference between hot melt adhesive blocks and other forms like pellets?

The primary difference is physical form and typical application method. Blocks are designed for manual loading into specific melt tanks or handguns. Pellets and granules are more suited to automated bulk handling systems with hopper feeders. The adhesive performance itself is defined by its chemical formulation, not its shape, so similar performance can often be found in different formats.

Can I use any hot melt block in my manual glue gun?

Compatibility is important. Manual glue guns are designed to accept sticks of specific diameters (e.g., 11mm, 12mm, 45mm). You must use block sticks that match your gun's chamber size. Furthermore, you should select a stick formulation (e.g., general-purpose, high-temperature, wood-specific) appropriate for your project materials and required bond strength.

How should I store unused hot melt adhesive blocks?

Hot melt blocks should be stored in a cool, dry place away from direct sunlight and heat sources. Good storage conditions help maintain the adhesive's performance and prevent the blocks from softening, sticking together, or attracting dust before use. Keeping them in their original packaging until needed is generally recommended.

Are hot melt adhesive blocks suitable for outdoor use or high-temperature environments?

It depends entirely on the specific formulation. Standard EVA-based blocks may soften or fail in high heat or under prolonged UV exposure. For such demanding applications, you would need to select blocks made from advanced polymers like polyamides or polyolefins, which offer higher heat resistance and environmental durability. Always check the manufacturer's specifications for temperature and environmental ratings.

English

English 中文简体

中文简体