Inside Pressure-Sensitive Hot Melt Adhesives: Manufacturing in Practice

Pressure-sensitive hot melt adhesives (PSHMAs) are widely used in labels, tapes, hygiene products, medical disposables, and protective films. In everyday production, they are valued for instant tack, clean processing, and consistent bonding without the need for curing agents or solvents. The following article explains how these adhesives are composed, how they bond in block form during use, and how they are manufactured in real industrial settings.

Pressure-sensitive hot melt adhesives are used across many industries because they adapt well to different substrates and production conditions.

In the labeling industry, they are widely used for bottle labels, logistics labels, and promotional stickers. The instant bonding allows labels to be applied at high speeds while maintaining accurate placement.

In packaging, pressure-sensitive hot melt adhesives are found in tapes, seals, and protective films. Their stable tack ensures packaging remains closed during transport but can still be opened when needed.

The hygiene and medical sectors use these adhesives in products such as diapers, sanitary napkins, and disposable medical items. Here, flexibility, skin compatibility, and secure bonding are essential.

In industrial tapes and films, PSHMAs provide consistent adhesion to metal, plastic, or painted surfaces while allowing controlled removal in certain applications.

Advantages in Real Production Settings

From a manufacturing perspective, pressure-sensitive hot melt adhesives offer several practical advantages:

High production efficiency due to immediate bonding

Reduced equipment complexity compared to liquid or solvent-based systems

Lower environmental impact because no solvents are involved

Stable performance across long production runs

Compatibility with automated coating and laminating equipment

These benefits help manufacturers maintain consistent quality while controlling operating costs.

Limitations and Considerations

Despite their versatility, pressure-sensitive hot melt adhesives are not suitable for every application. Their limitations should be understood during material selection.

They generally have limited high-temperature resistance, meaning they may soften or lose adhesion in hot environments. Long-term exposure to heat or direct sunlight can affect performance.

They are also less suitable for permanent structural bonding, as their bonding mechanism relies on surface contact rather than chemical curing.

Proper temperature control during application is essential. Overheating can degrade the adhesive, while insufficient heat may lead to poor coating and weak adhesion.

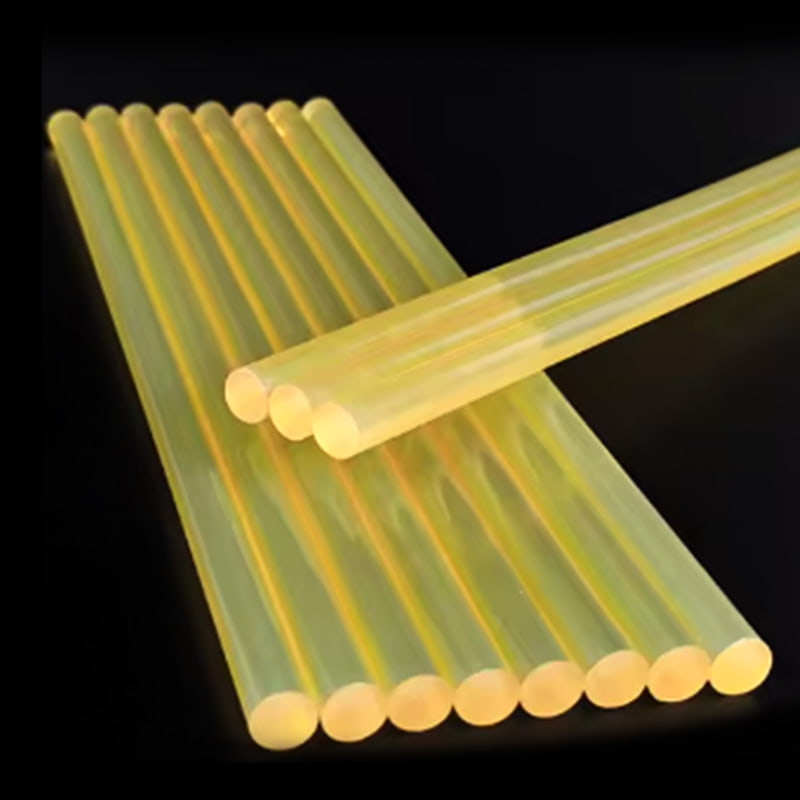

Storage and Handling in Practice

In real-world use, pressure-sensitive hot melt adhesives are typically supplied as blocks, pellets, or pillows. They should be stored in clean, dry conditions away from direct heat sources. Moisture is generally less critical than for reactive adhesives, but contamination can still affect melting and coating quality.

During equipment shutdowns, operators usually lower temperatures gradually to avoid thermal stress on both adhesive and machinery.

Composition of Pressure-Sensitive Hot Melt Adhesives

Understanding the key components and their role in adhesive performance

Pressure-sensitive hot melt adhesives are formulated to balance tack, cohesion, and processability. While specific recipes vary by application, PSHMAs are built from several core components, each contributing a defined function.

Base Polymers

The base polymer provides the adhesive's backbone and determines its elastic and cohesive properties. Common choices include styrenic block copolymers (such as SIS or SBS), polyolefins, and, in some cases, acrylic-based polymers. These materials allow the adhesive to remain permanently tacky at room temperature while maintaining internal strength. The polymer selection affects temperature resistance, flexibility, and long-term aging behavior.

Tackifying Resins

Tackifiers are added to improve surface wetting and immediate adhesion. They help the molten adhesive spread quickly over the substrate and develop instant grab under light pressure. Hydrocarbon resins, rosin derivatives, and terpene-based resins are widely used. The compatibility between the tackifier and base polymer is critical; poor matching can phase separation or unstable viscosity.

Plasticizers and Oils

Plasticizers adjust softness and flexibility. In pressure-sensitive systems, mineral oils or synthetic oils are commonly used to fine-tune viscosity and tack at application temperature. Proper dosing helps ensure the adhesive flows well when heated but remains stable during storage and use.

Stabilizers and Additives

Antioxidants and thermal stabilizers protect the adhesive during repeated heating cycles. Small amounts of fillers, UV stabilizers, or colorants may also be included, depending on end-use requirements.

Together, these components form a balanced system that delivers reliable tack, controlled flow, and consistent bonding performance in real production environments.

Bonding Mechanism of Hot Melt Pressure-Sensitive Adhesive Blocks

Hot melt pressure-sensitive adhesive blocks are supplied in solid form and melted before application. Their bonding mechanism differs from reactive or curing adhesives and relies on physical interactions rather than chemical reactions.

- Thermal activation

The adhesive block is heated until it becomes molten and homogeneous.

Heating reduces viscosity, allowing the adhesive to flow and coat surfaces evenly.

- Surface wetting

When applied, the molten adhesive spreads across the substrate surface.

Good wetting ensures close contact with surface irregularities.

- Pressure application

Light pressure is applied through rollers, laminators, or manual pressing.

Pressure helps eliminate air gaps and increases contact area.

- Immediate tack development

As the adhesive cools, it transitions from molten to viscoelastic state.

The material remains tacky, allowing instant adhesion without curing time.

- Viscoelastic balance

The adhesive's elastic component provides cohesion, preventing residue or splitting.

The viscous component maintains surface stickiness for repositioning, if required.

- Temperature stabilization

Once cooled to ambient temperature, the adhesive reaches stable performance.

Bond strength remains consistent as long as it stays within its designed temperature range.

This mechanism explains why pressure-sensitive hot melt adhesives are well suited for high-speed labeling, tapes, and hygiene products, where fast bonding and clean release are required.

Manufacturing Process of Hot Melt and Liquid Adhesives

Production process of pressure-sensitive hot melt adhesives

The manufacturing of pressure-sensitive hot melt adhesives follows a controlled and repeatable process. While equipment design may vary, the core stages are similar across production facilities.

Raw material preparation

Polymers, resins, oils, and additives are inspected and staged.

Materials are checked for moisture content and consistency before use.

Initial heating and polymer melting

Base polymers are added to a heated mixer or reactor.

Temperature is raised gradually to soften and melt the polymer without degradation.

Addition of tackifiers and plasticizers

Tackifying resins are introduced slowly to ensure proper compatibility.

Plasticizers or oils are added to adjust viscosity and flow characteristics.

Mixing and homogenization

Mechanical agitators or twin-screw mixers blend the molten materials.

Mixing continues until a uniform, stable adhesive mass is achieved.

Stabilization and filtration

Antioxidants and stabilizers are added to protect against thermal aging.

The molten adhesive may pass through filters to remove impurities.

Cooling and forming

The adhesive is cooled in a controlled manner.

It is shaped into blocks, pillows, or pellets, depending on customer requirements.

Packaging and quality control

Finished products are packed in protective materials to prevent contamination.

Samples are tested for viscosity, tack, peel strength, and thermal stability.

English

English 中文简体

中文简体