How to Choose the Right Hot Melt Adhesive?

Hot melt adhesive (HMA) is a versatile bonding solution widely used in industries like packaging, woodworking, textiles, electronics, and automotive. Its fast curing speed, strong adhesion, and environmental friendliness make it a top choice for many manufacturing and assembly needs. However, with various types, formulas, and specifications available, selecting the right hot melt adhesive requires careful consideration of multiple factors to ensure optimal bonding performance and cost-effectiveness. This guide breaks down the key steps and considerations to help you make an informed decision.

1. Clarify Your Application Scenarios & Bonding Materials

The first and most critical step is to define your specific use case and the materials you need to bond. Different materials have unique surface properties (e.g., porosity, polarity, texture), which directly affect adhesive compatibility.

Common Material Pairs & Matching HMA Types

• Paper, Cardboard, & Packaging: Choose low-melt (100–130°C) or standard-melt (130–160°C) ethylene-vinyl acetate (EVA) hot melt adhesives. They offer good adhesion to porous materials, fast setting, and cost-effectiveness, ideal for carton sealing, label bonding, or bookbinding.

• Wood & Furniture: Opt for EVA or polyolefin (PO) hot melts with high viscosity and heat resistance. For load-bearing structures (e.g., furniture assembly, wood edge banding), consider reactive hot melt adhesives (PUR) — they form chemical bonds with wood, providing superior durability and water resistance.

• Textiles, Fabrics, & Nonwovens: Select low-temperature EVA or amorphous polyalphaolefin (APAO) hot melts. These adhesives have soft flexibility, won’t damage delicate fabrics, and work well for garment hemming, diaper bonding, or textile lamination.

• Electronics & Appliances: Use low-odor, high-temperature-resistant polyamide (PA) or polyester (PES) hot melts. They offer excellent adhesion to plastics (e.g., ABS, PP), metals, and glass, while meeting the strict requirements of electronics for thermal stability and insulation.

• Automotive Parts: Choose high-performance PES, PA, or PUR hot melts. They withstand extreme temperatures (-40°C to 150°C), vibration, and moisture, suitable for bonding interior parts (e.g., door panels, carpets) or under-hood components.

2. Consider Key Performance Requirements

Beyond material compatibility, your application’s working conditions and quality standards determine the adhesive’s performance parameters. Focus on these core factors:

a. Melting Temperature (Application Temperature)

• Low-temperature (80–120°C): Best for heat-sensitive materials (e.g., fabrics, foam, thin plastics) to avoid deformation or damage.

• Standard-temperature (120–160°C): Universal choice for most common materials (paper, wood, general plastics) — balances performance and energy efficiency.

• High-temperature (160–200°C): Required for high-heat environments (e.g., automotive under-hood, industrial machinery) or bonding heat-resistant materials (e.g., metals, high-density plastics).

b. Setting Time (Open Time & Curing Speed)

• Open Time: The time between adhesive application and bonding (when the adhesive is still sticky enough to form a bond). Short open time (5–30 seconds) suits high-speed production (e.g., packaging lines); long open time (30–120 seconds) is needed for large parts or manual assembly.

• Curing Speed: How quickly the adhesive hardens and achieves full bond strength. Fast curing (seconds to minutes) boosts production efficiency; slow curing may be necessary for materials that need time to align (e.g., furniture edge banding).

c. Adhesion Strength & Durability

• Peel Strength: Resists the force of peeling two bonded materials apart — critical for flexible products (e.g., textiles, labels).

• Shear Strength: Withstands the force of sliding or pulling materials in parallel — essential for load-bearing applications (e.g., wood assembly, automotive parts).

• Environmental Resistance: Check if the adhesive needs to resist water, humidity, UV light, chemicals (e.g., oils, solvents), or temperature fluctuations. For outdoor or wet environments, prioritize PUR, PES, or PA hot melts over standard EVA.

d. Viscosity

Viscosity (measured in mPa·s) affects how the adhesive flows and penetrates materials:

• Low viscosity (500–5,000 mPa·s): Flows easily, penetrates porous materials (e.g., paper, wood) deeply — good for thin substrates or gap-filling.

• High viscosity (5,000–50,000 mPa·s): Flows slowly, stays in place on vertical surfaces — ideal for thick materials, large gaps, or preventing adhesive bleed-through (e.g., wood edge banding, fabric bonding).

3. Evaluate Processing & Operational Factors

The adhesive must match your production equipment and workflow to avoid operational issues and cost waste:

a. Adhesive Form

Hot melt adhesives come in different forms to fit various application tools:

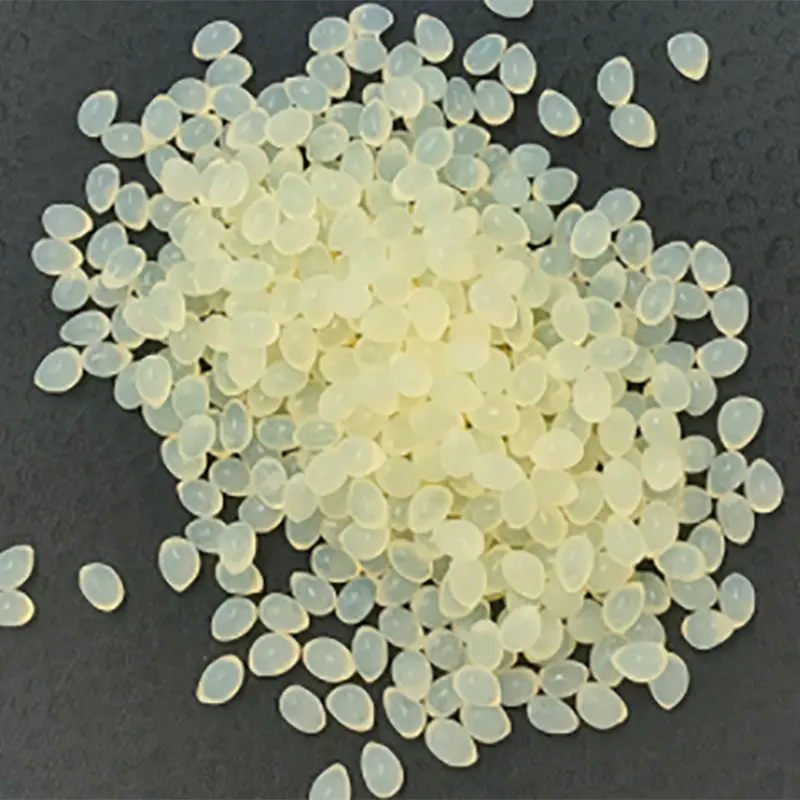

• Pellets/Granules: Most common form, used with hot melt guns, extruders, or automated dispensing systems — suitable for large-scale production.

• Sticks: Designed for handheld hot melt guns — ideal for small batches, repairs, or manual work (e.g., crafts, small-scale assembly).

• Films/Tapes: Pre-cut into sheets or rolls, easy to apply for lamination (e.g., textile, plastic film bonding) — ensures uniform adhesive distribution.

• Powders: Used for rotational molding or coating applications (e.g., metal surface bonding) — melts and adheres when heated.

b. Equipment Compatibility

Ensure the adhesive is compatible with your existing dispensing equipment (e.g., temperature range of the hot melt machine, nozzle size, pump type). For example, high-viscosity adhesives require machines with powerful pumps and large nozzles; low-temperature adhesives work with standard low-heat guns.

c. Cost-Effectiveness

Balance performance with total cost, not just the adhesive’s unit price:

• Coverage Rate: High-coverage adhesives (e.g., low-viscosity formulas that spread thinly) reduce the amount needed per application, cutting long-term costs.

• Energy Consumption: Low-temperature adhesives save energy on heating the machine, especially for high-volume production.

• Waste Reduction: Adhesives with stable viscosity and consistent melting avoid clogs, leaks, or uneven application — minimizing material waste and equipment downtime.

4. Comply with Environmental & Regulatory Standards

Depending on your industry and target markets, the adhesive must meet relevant safety and environmental regulations:

• Food Packaging: Choose FDA-approved, food-safe hot melts (e.g., EVA or PO formulas without toxic additives) to ensure no migration of harmful substances into food.

• Electronics: Comply with RoHS, REACH, or UL standards — select adhesives free of heavy metals (e.g., lead, mercury) and volatile organic compounds (VOCs).

• Medical Devices: Use medical-grade hot melts (ISO 10993 certified) that are biocompatible, non-toxic, and sterile, suitable for bonding medical masks, catheters, or surgical tools.

• Environmental Protection: Prioritize low-VOC, recyclable hot melts to meet global sustainability requirements (e.g., EU ECOCERT, US EPA standards) and reduce environmental impact.

5. Test Before Mass Production

Never skip small-batch testing — it’s the only way to verify if the adhesive meets your actual needs. Conduct these key tests:

• Bond Strength Test: Measure peel and shear strength using professional equipment (e.g., tensile testing machine) to ensure it meets your quality standards.

• Environmental Aging Test: Expose bonded samples to extreme temperatures, humidity, UV light, or chemicals for a period (e.g., 1–3 months) to check durability.

• Production Simulation Test: Run the adhesive on your actual production line to test processing stability (e.g., no clogs, uniform application) and production efficiency.

6. Partner with a Reliable Supplier

A trusted hot melt adhesive supplier provides more than just products — they offer technical support to solve bonding issues. Look for suppliers with:

• Rich industry experience and customized formula capabilities (e.g., adjusting viscosity, setting time for your specific application).

• Comprehensive technical services (e.g., on-site testing, equipment debugging, after-sales support).

• Stable supply chains to avoid production interruptions, especially for high-volume orders.

Final Tips for Selection

1. Start with sample testing — most suppliers offer free samples; test 2–3 candidates to compare performance.

2. Don’t overspecify: Choose a cost-effective universal adhesive for simple applications (e.g., packaging) instead of high-end formulas that add unnecessary cost.

3. Consider future scalability: If your production line may upgrade to higher speed or expand to new materials, select an adhesive that can adapt to changing needs.

Choosing the right hot melt adhesive is a balance of material compatibility, performance requirements, processing feasibility, and cost. By following this guide, you can avoid common mistakes (e.g., poor adhesion, material damage, production downtime) and select an adhesive that optimizes your bonding quality and production efficiency. Always consult with your adhesive supplier for personalized recommendations based on your specific application details — their expertise can save you time and resources in the long run.

English

English 中文简体

中文简体