What are the advantages of hot melt adhesive in the application of label and express bag industry?

Hot melt adhesive is a kind of plastic adhesive, which is an environmentally friendly chemical product. It is widely used because of its high bonding strength and fast speed. Hot melt adhesive is non-toxic and odorless, and is an energy-saving organic chemical product. Environmentally friendly hot melt adhesive has passed a variety of international environmental protection product certifications. It is not easy to cause environmental pollution to the natural environment during the processing and application process.

The advantages of hot melt adhesive in the label industry

In recent years, with the rapid development of e-commerce, logistics and transportation, product packaging, cargo identification and other industries have also grown significantly, and the label industry and the sticky label industry driven by these industries are developing rapidly. Label hot-melt adhesive is mainly used for labels, paper products, and labeling composite hot-melt pressure-sensitive adhesives.

In addition, there are removable label adhesives, which do not contain harmful or toxic substances, and fully comply with national safety standards. Its adhesion performance, re-peeling performance and storage stability performance and other indicators have reached the leading level at home and abroad. It does not contain pollutants to the environment, and it will not damage the surface of the material and leave glue stains after repeated shifting, bonding and tearing. It is a green and environmentally friendly product. Widely used in furniture, glass and other materials.

Application of hot melt adhesive in express delivery industry

With the popularity of online shopping, more and more express goods and express orders need to be packaged and pasted. Hot melt adhesives are also widely used in the express delivery industry, such as the sealing of various express bags, the pasting of express orders, the sealing of bubble bags, and the pasting of kraft paper envelopes. The courier bag hot melt adhesive with excellent low temperature performance developed by the express bag industry can effectively paste the express bag and achieve the effect of breaking the bag.

As an environmentally friendly adhesive with excellent performance, hot melt adhesive has high safety and reliability. It is gradually replacing traditional solvent adhesives, and the downstream application scope is constantly expanding. In addition to the packaging, printing, labeling, shoe materials and other industries mentioned above, there are good development prospects in the automobile, hygiene products, new energy and other environmental protection product industries.

What Are the Production Steps of Hot Melt Adhesive?

The production of hot melt adhesive is a controlled industrial process that combines chemistry, mechanical mixing, and quality management. Although formulations vary, the general production steps follow a similar structure.

Raw material preparation

Polymers (such as EVA, polyolefin, or polyurethane) are prepared as the base materials.

Tackifiers, waxes, stabilizers, antioxidants, and fillers are selected according to the required performance.

All raw materials are inspected to ensure consistency and compliance with specifications.

Weighing and batching

Each component is weighed accurately based on the formulation.

Precise batching is critical, as small deviations can affect viscosity, open time, and bonding strength.

Heating and melting

Polymers and additives are introduced into a heating kettle or reactor.

The materials are gradually heated to a controlled temperature until fully melted.

Temperature control is essential to avoid thermal degradation.

Mixing and homogenization

Mechanical stirrers or twin-screw extruders are used to mix the molten materials.

The goal is to achieve a uniform, homogeneous adhesive with stable viscosity.

Filtration and degassing

The molten adhesive may pass through filters to remove impurities.

Air bubbles are reduced to improve application stability.

Cooling and shaping

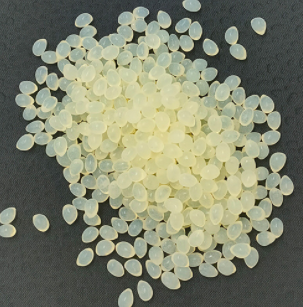

The adhesive is cooled and shaped into granules, blocks, pillows, or sticks using molds or pelletizing systems.

Packaging and labeling

Finished products are packed in moisture-resistant bags or cartons.

Labels include batch numbers, specifications, and storage instructions.

Quality inspection and storage

Samples are tested for viscosity, softening point, and bonding performance.

Products are stored in dry conditions before shipment.

These steps reflect actual industrial practices and ensure that hot melt adhesives perform consistently in real production environments.

What Are the Types of Hot Melt Glues and Their Respective Characteristics?

Hot melt glues can be classified according to their chemical base and performance characteristics. Each type is designed for specific applications and processing conditions.

EVA (Ethylene Vinyl Acetate) Hot Melt Glue

EVA hot melt glue is one of the widely used types. It offers good flexibility, moderate bonding strength, and cost efficiency. EVA adhesives are commonly used in carton sealing, bookbinding, and general packaging. However, their heat resistance and aging performance are limited compared to more advanced formulations.

Polyolefin (PO) Hot Melt Glue

Polyolefin-based hot melt glues provide improved heat resistance, lower odor, and better thermal stability. They are often used in food packaging and hygiene products. PO adhesives generally have cleaner processing behavior but are slightly higher in cost than EVA.

Polyamide (PA) Hot Melt Glue

Polyamide hot melt glues are known for strong adhesion and resistance to oils, chemicals, and higher temperatures. They are widely used in automotive, electronics, and filter assembly. Their processing temperature is higher, and they require more robust equipment.

PUR (Polyurethane Reactive) Hot Melt Glue

PUR hot melt glue combines hot melt application with moisture curing. After cooling, it reacts with moisture in the air to form a durable chemical bond. PUR adhesives are commonly used in woodworking, furniture edge banding, and high-performance assembly. They offer strength and resistance but require special sealed equipment and careful handling.

Metallocene-Based Hot Melt Glue

Metallocene hot melt glues provide stable viscosity, good aging resistance, and clean appearance. They are suitable for high-speed automated packaging lines and consistent bonding needs.

Each type has its own balance of cost, performance, and processing requirements. Selecting the right hot melt glue depends on substrate materials, operating conditions, and long-term performance expectations.

Advantages and Disadvantages of Water Resistant Hot Melt Glue Granules

Water resistant hot melt glue granules are increasingly used in packaging, woodworking, and outdoor-related applications. Their performance should be evaluated from several practical aspects.

Advantages

- Improved moisture resistance

Water resistant formulations maintain bonding strength in humid environments or during short-term water exposure. This is particularly important for packaging stored in warehouses or transported under varying climate conditions.

- Wide application range

These granules can bond paper, cardboard, wood, coated surfaces, and some plastics. Their versatility reduces the need for multiple adhesive types in one production line.

- Granular form benefits

Granules allow precise feeding in automatic hot melt machines. They melt evenly, reduce waste, and support stable production control.

- Fast setting and production efficiency

Like hot melt adhesives, water resistant granules set quickly after application, supporting high production speeds and reducing waiting time.

Cleaner processing compared to liquid adhesives

They are solvent-free and generate minimal emissions during application, improving workplace conditions.

Disadvantages

- Higher material cost

Water resistant hot melt glue granules are generally more expensive than standard EVA formulations due to specialized polymers and additives.

- Limited long-term water immersion resistance

While they resist moisture and humidity well, hot melt adhesives are not designed for continuous water immersion or underwater use.

- Temperature sensitivity

Although water resistant, some formulations may still soften under high temperatures, which can affect bonding in hot environments.

- Equipment requirements

Stable temperature control is required to ensure proper melting and application. Inconsistent heating can reduce water resistance performance.

- Storage considerations

Granules must be stored in dry conditions. Exposure to moisture during storage can affect melting behavior and adhesive quality.

Hot melt adhesives are a mature and practical bonding solution built on well-established industrial processes. From carefully controlled production steps to diverse adhesive types and specialized water resistant formulations, each stage reflects real manufacturing needs rather than theoretical design. Understanding how hot melt adhesives are made, how different types perform, and where water resistant hot melt glue granules excel or fall short helps manufacturers make informed decisions. By matching adhesive selection to actual working conditions, production efficiency and bonding reliability can be improved in a sustainable and cost-aware manner.

English

English 中文简体

中文简体